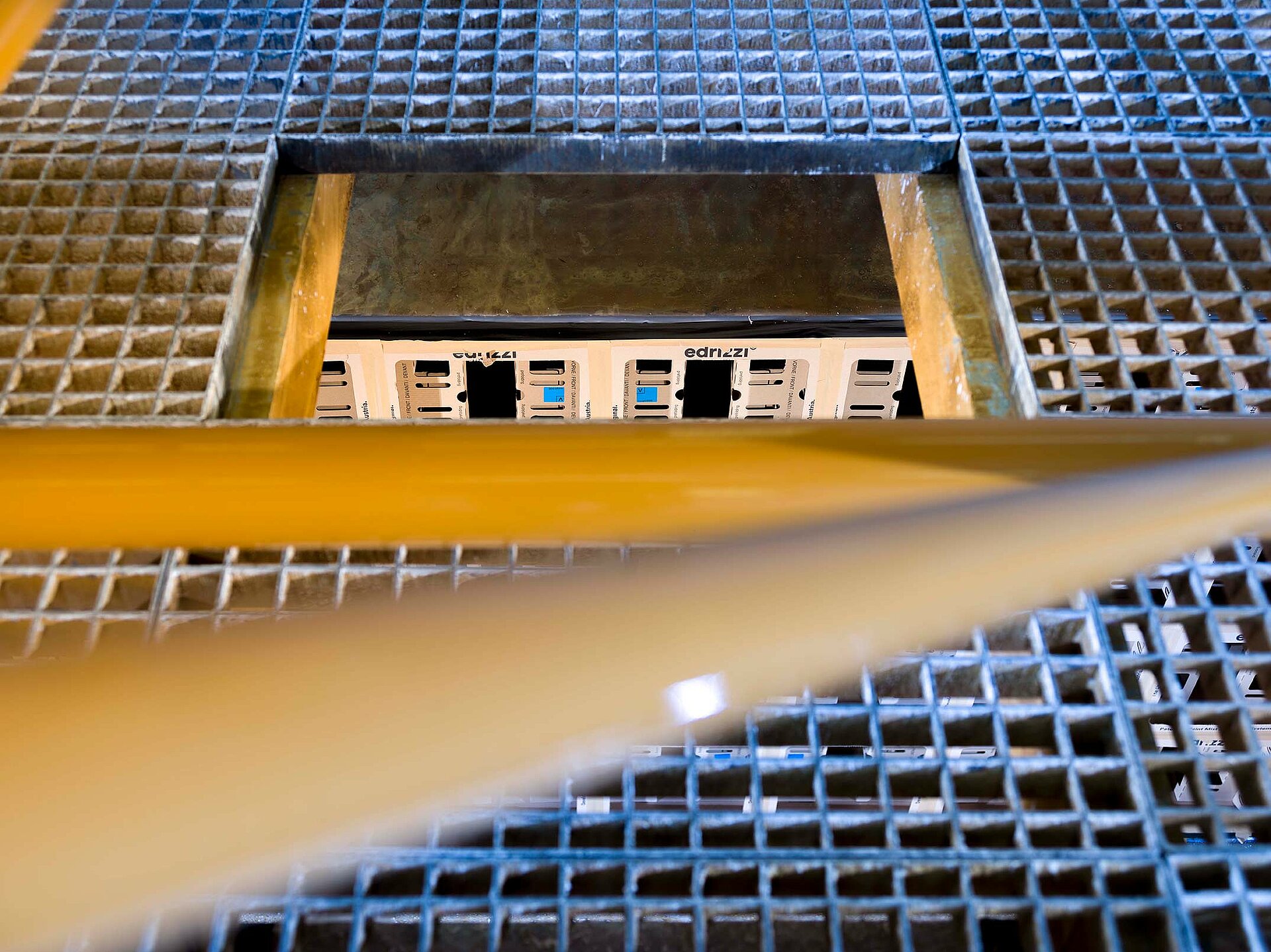

The patented edrizzi® Dry Mist Separator System consists of two flexibly combinable stages: paint mist separation with the edrizzi® Vario cardboard boxes and at least one matching edrizzi® post-filter stage. These two components are connected to each other in a modular system using a sheet steel construction. Only by using the original system components can the system achieve its revolutionary absorption capacity of up to 97% of overspray.

System diversity for every surface material in the paint industry

With numerous types of paint mist arrestors, pre-filters, and five types of post-filters, the edrizzi® system offers an unrivalled variety of solutions that have been proven in countless paint applications, regardless of size, air supply, and application method. The edrizzi® system reliably separates all types of surface materials – whether coarse overspray, fine particles, adhesives, foaming surface materials or dry paint dust.

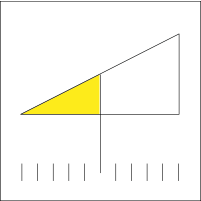

Thanks to its clear system architecture, the edrizzi dry separation system can be seamlessly integrated into a wide variety of plant types, whether new or retrofitted. The edrizzi® system can be installed horizontally, vertically, or in a combination of both. Size and design are variably scalable, and the simple handling is consistently geared towards economic and ecological benefits. All edrizzi® system components are delivered flat and disassembled to facilitate handling and simplify logistics. Assembly is quick and intuitive.

Cost-effectiveness

Switching from wet to dry painting with edrizzi® reduces your painting costs in the long term – during operation, disposal, and maintenance:

- No water consumption for paint mist separation

- No disposal of paint sludge as hazardous waste

- No discharge of paint sludge – saves time and personnel

- No chemicals such as coagulants, defoamers or bactericides

- Less corrosion on the booth technology

- No pump technology – no associated maintenance costs

- Less cleaning required in the paint booth

- Compact, disassembled delivery – saves storage and transport costs

Efficiency

The edrizzi® system impresses with its high separation efficiency and low maintenance requirements:

- Separation efficiency of up to 97% when used correctly with a post-filter

- Absorption capacity of 100 kg/m² and more in the paint mist separation stage – depending on the surface material

- Constant separation efficiency over long service life

Sustainability

With edrizzi®, you not only reduce your operating costs, but also your environmental impact:

- The saturated edrizzi® paint mist arrestors with dried paint residue can usually be recycled thermally at low cost

- No chemicals in the process – no potential hazards

- CO₂ reduction through low energy consumption

- Use of recyclable materials such as paper and polyester