Our team can draw on many years of experience when planning your system: Research and development in our in-house technical center, countless proven systems in operation, and close cooperation with renowned plant manufacturers testify to our expertise in the field of paint mist arrestors and paint filter systems. Experienced members of our team or our international trading partners will plan your economical, sustainable, and ergonomic paint system—as a retrofit or new system with edrizzi®.

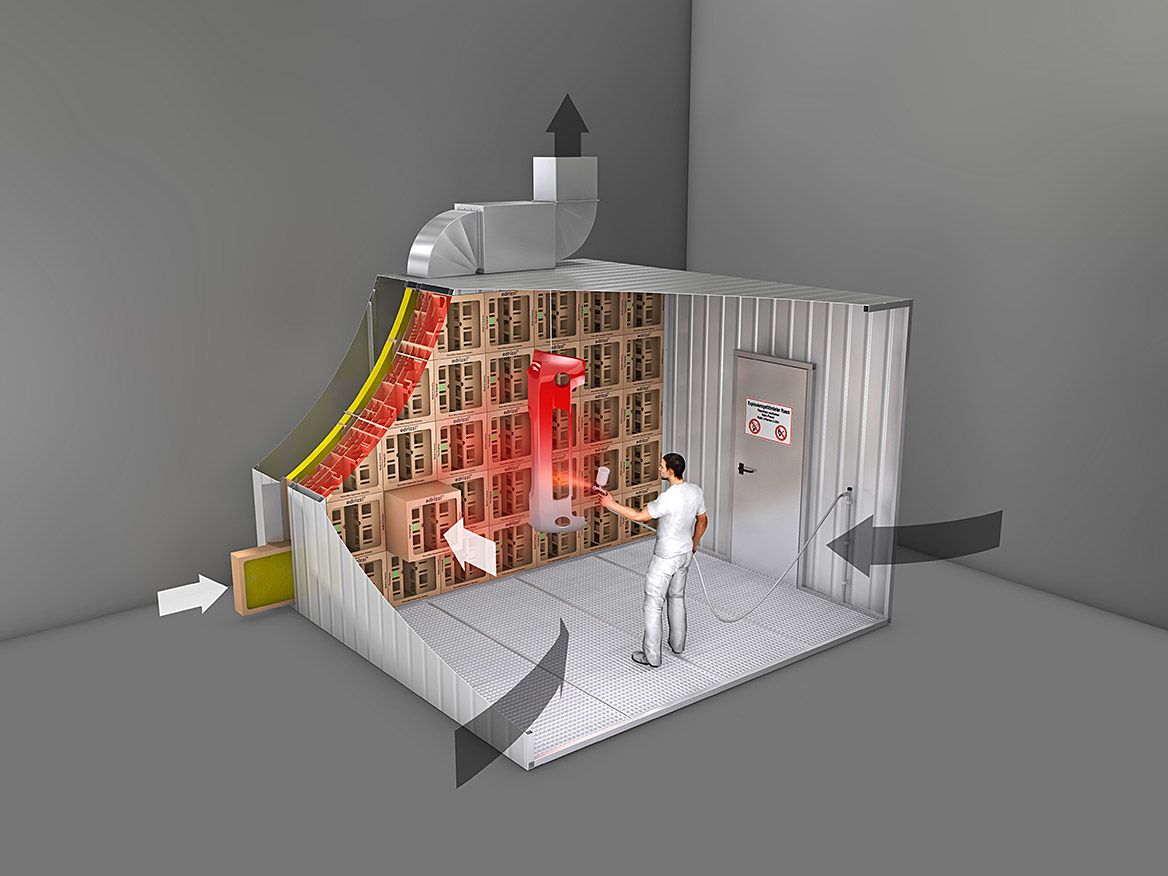

The base consists of a sheet metal body with an integrated edrizzi® system comprising paint mist arrestor and at least one, maximum two secondary filter stages plus an exhaust air fan. The secondary filters in the exhaust air body can be changed on the side independently of the paint mist arrestor. Depending on the application and surface material, all elements of the edrizzi® system are available for secondary filtering.

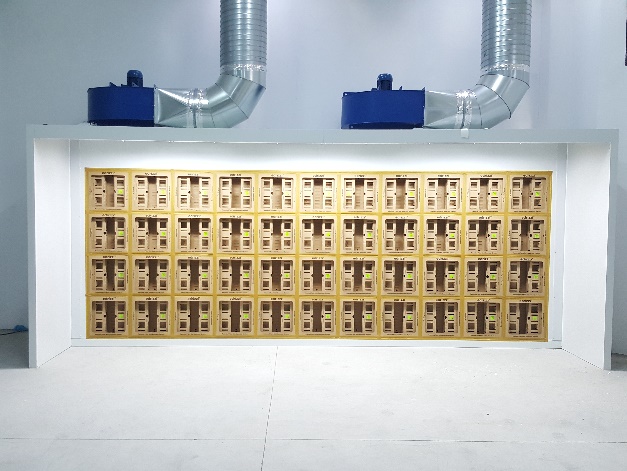

ULF stands for recirculation filter technology and has been used in the paint industry for many years. The combination of the edrizzi® system with ULF results in a highly effective painting concept that achieves up to 99 percent separation for fast-drying surface materials. With this variant, secondary filter service life of over one year is achieved.

The system consists of a galvanized sheet steel housing, an edrizzi® Vario paint mist arrestor, an extraction box, an endless recirculation filter fleece, a drive system, and an extraction unit.

The edrizzi® Vario boxes separate most of the paint mist. The circulating filter fleece behind them acts as a secondary filter. It catches the remaining fine dust and transports it continuously to the cleaning area. A self-cleaning dust collector, developed by the edrizzi® team, serves as the cleaning station. Here, the dried paint material is extracted from the transport medium and collected in a 200-liter tank. This process ensures that the recirculation filter remains constantly receptive. As with conventional spray booths, the air is extracted by extraction fans.

edrizzi® and ULF can be installed either vertically or horizontally, like all separation systems from edrizzi®. Retrofitting existing systems is simple and inexpensive. The edrizzi® and ULF system is one of the cleanest solutions for all applications in the paint industry – from simple manual spray booths and high-performance underfloor variants to the edrizzi® and ULF system as part of automated paint lines.

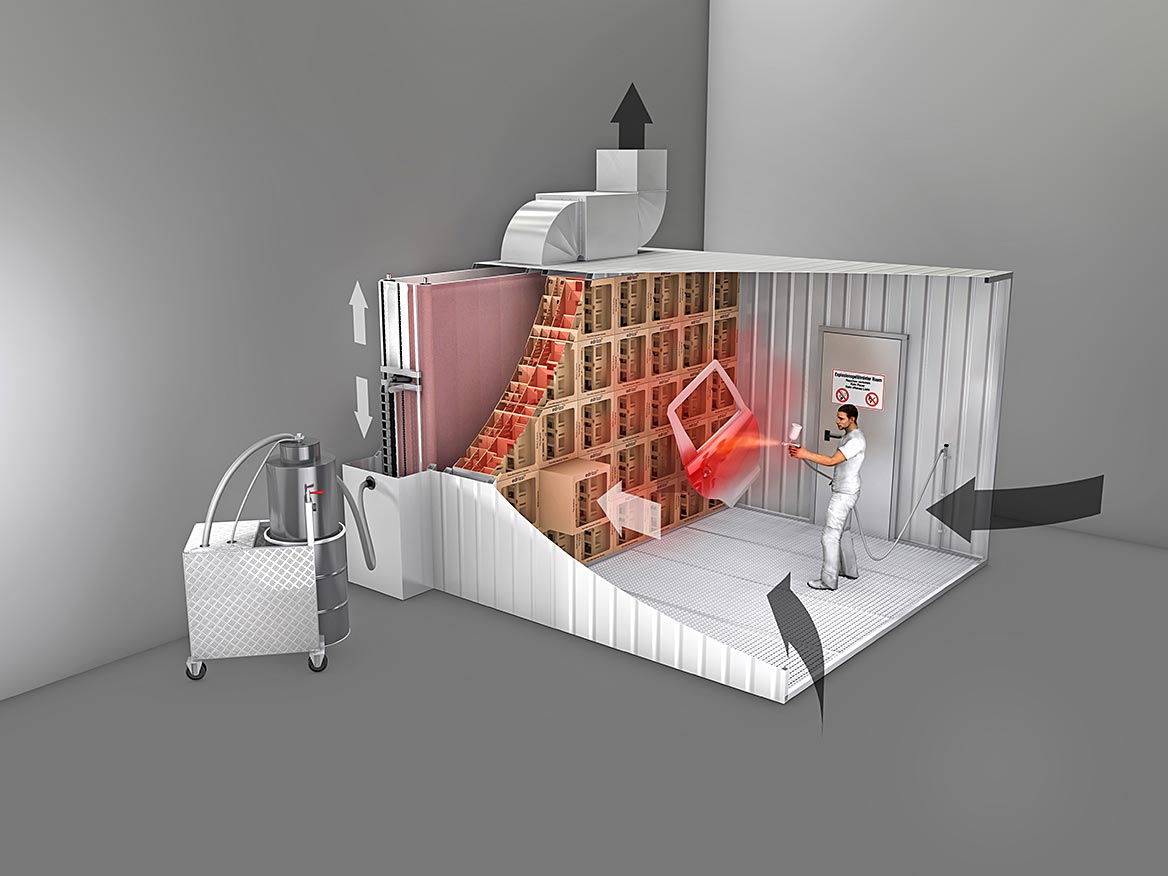

The edrizzi® and ABRO system combines an edrizzi® Vario paint mist arrestor wall with an automatically timed, self-rolling filter medium as a secondary filter. This combination results in a highly effective painting concept with up to 99% separation for sticky surface materials. Depending on the application, service life of several weeks can be achieved for the edrizzi® secondary filtration.

The concept consists of a galvanized sheet steel housing, an edrizzi® Vario paint mist arrestor, an extraction box, a secondary filter mat, and a drive system. The filter flow naffi®, developed exclusively for the edrizzi® system, serves as the main secondary filter.

The edrizzi® Vario boxes are the first filter stage and separate most of the paint mist. The secondary filtering separates the fine dust, is automatically cycled and rolled up again. The saturated filter mat can be easily and quickly replaced via the side access, regardless of the saturation level of the Vario boxes. As with conventional spray booths, the air is extracted by extraction fans. Like all separation systems from edrizzi®, edrizzi® and ABRO can be installed either upright or horizontally. Retrofitting to existing systems is simple and inexpensive.

The edrizzi® and ABRO system is one of the cleanest solutions for all applications in the paint industry, from simple manual spray booths and powerful underfloor variants to the edrizzi® system as part of automated paint lines.