Liebherr Nenzing has been successfully using the edrizzi® dry separation system since 2009. The large-scale paint shop coats construction machine components in the characteristic Liebherr yellow—economically, ecologically, and with optimal ergonomics for the paint shop staff. The system has proven itself in multi-shift operation for over 15 years—a prime example of long-term operational reliability and sustainability.

Case Summary Liebherr Nenzing

- Used: Proven long-term use of edrizzi® dry separation since 2009 in the Liebherr-Heimer paint shop.

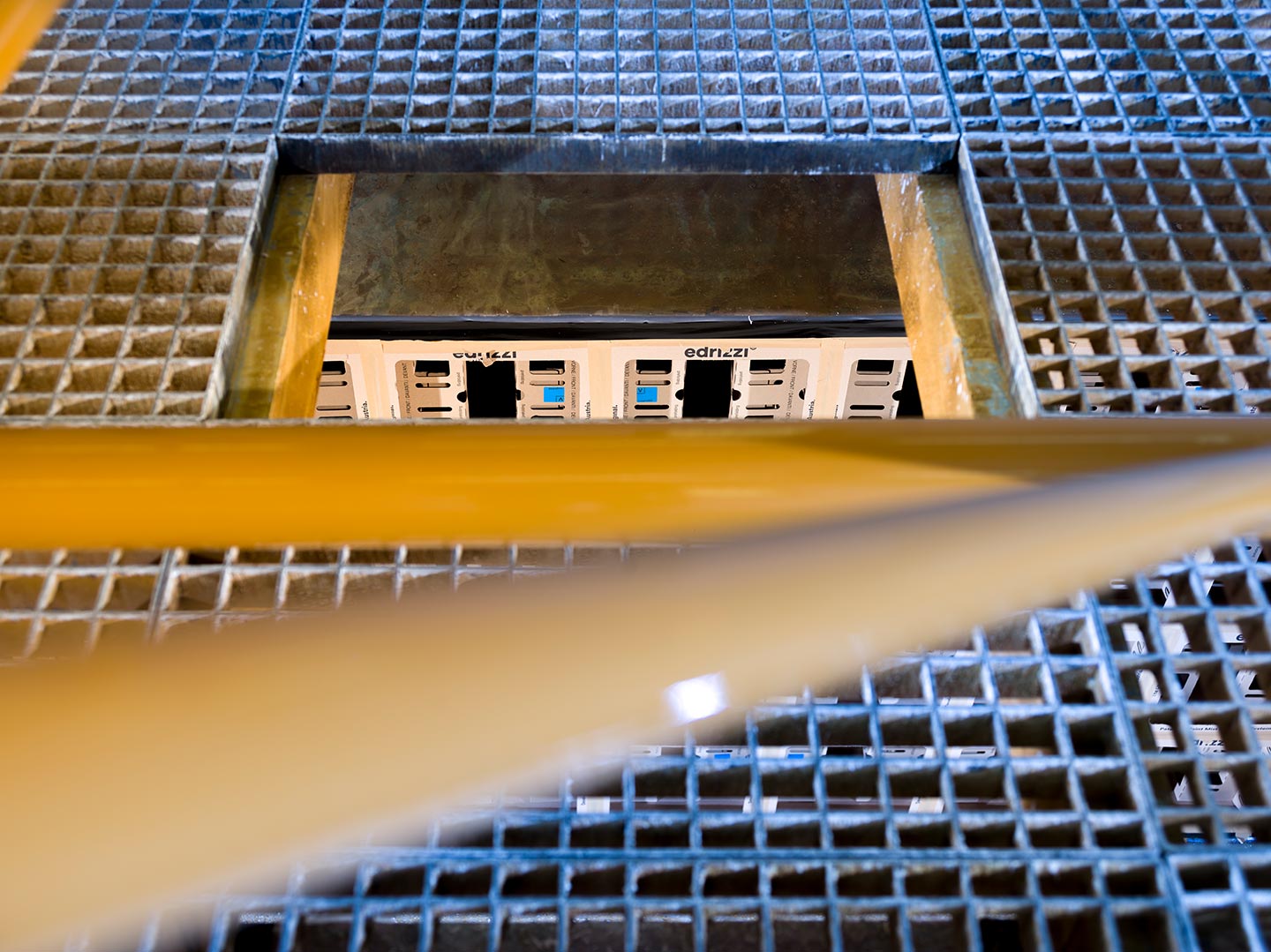

- Large-scale solution: 192 edrizzi® boxes on almost 80 m² of extraction area – specially designed for 15 m long crane boom modules.

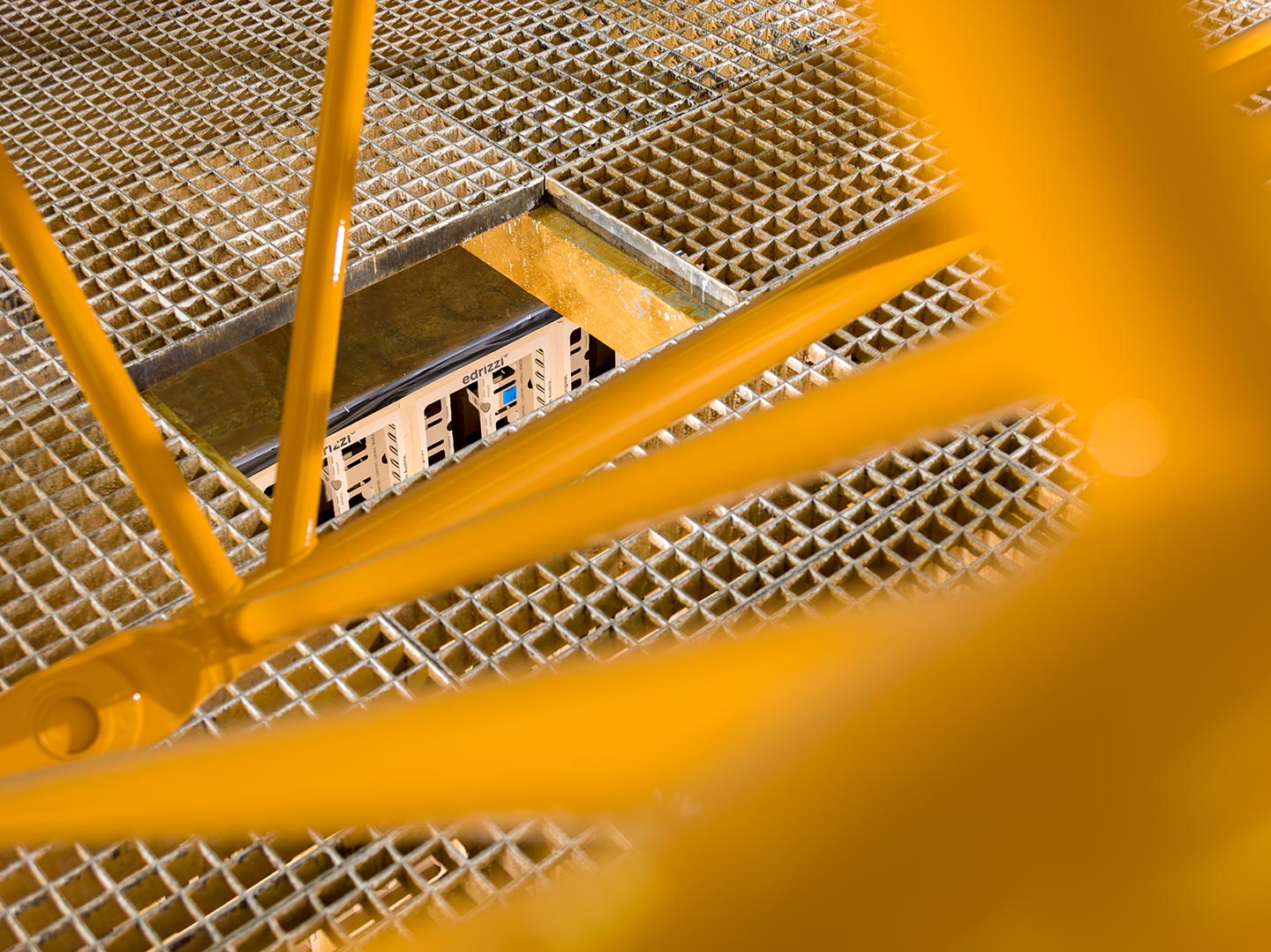

- Vertical underfloor installation: Enables ergonomic box replacement under gratings, independent of the painting area.

- Extremely high utilization: 2000 liters of paint per month, operation in 2- and 3-shift system – service life of the boxes up to 16 weeks.

- Flexible system change: edrizzi® vario medium can be easily adapted to vario rough when changing materials.

- Efficient air flow and filtration: Air calming zone and secondary filter stage ensure clean working air throughout the entire area.

Technical data Liebherr Nenzing

Location: Liebherr Nenzing, Austria

Installation: 2009

System: In-house paint shop for solvent-based paints

Paint mist arrestor: 192 edrizzi® vario medium, edrizzi® vario rough

Absorption capacity: up to 100 kg/m²

Service life: 12 to 16 weeks, depending on 2- or 3-shift operation

Surface material: RK-UHS for priming and 2-K-UR-HS topcoat, BASF / AKZO Nobel

In Liebherr Nenzing's large-scale Heimer painting facility for solvent-based paints, 192 edrizzi® vario medium and edrizzi® vario rough units with an absorption capacity of up to 100 kg/m² are installed. The service life of the system is 12 to 16 weeks, depending on whether it is operated in 2 or 3 shifts.